Polytech

Why testing is essential

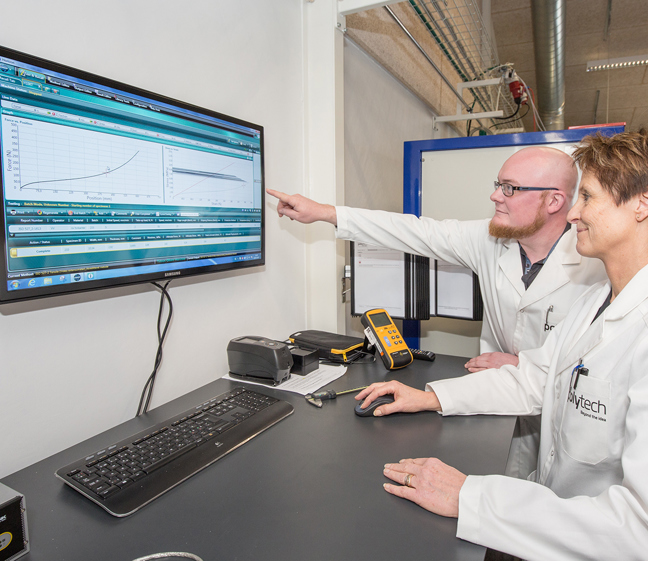

Certainty beats assumption. That is why we thoroughly test and validate all our engineering designs and solutions. And that is why we advise you to ensure that your wind turbine manufacturer (OEM) has similarly carried out all the necessary tests.

Enforce the recommended practices and keep in mind that in some cases, your solutions/assets need further or more extensive testing due to your project’s location or operational conditions.

Accredited test centers

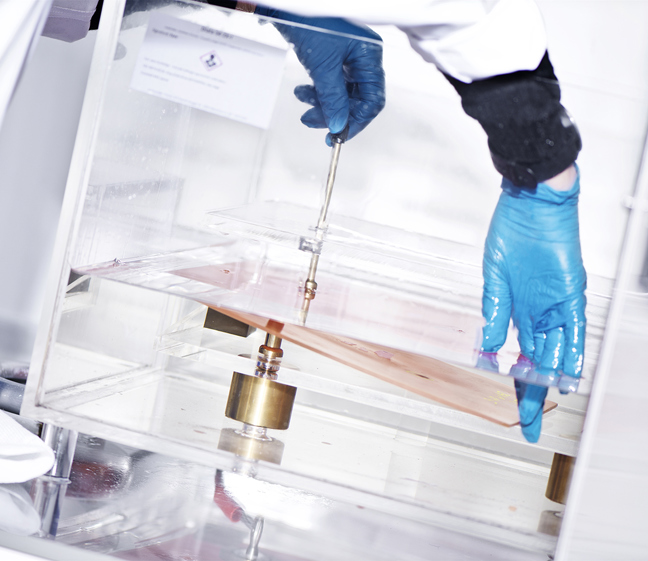

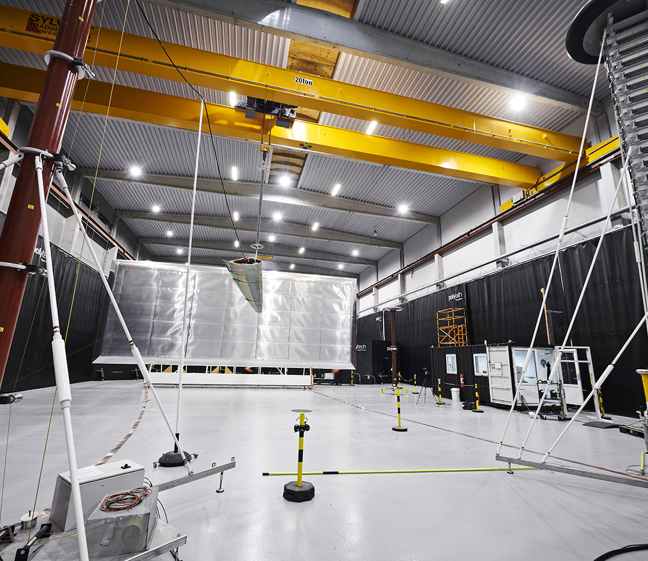

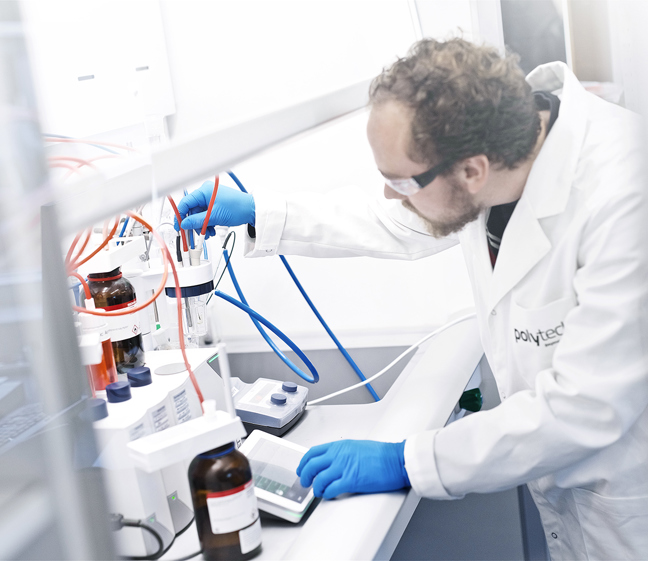

We have two test centers in Denmark – one specialized for lightning tests and the other for material tests.

Both test centers are accredited by DANAK (Danish Accreditation Fund, which is a member of ILAC) according to the ISO/IEC 17025 standard. This accreditation guarantees you test results at the highest quality.

External customers

As our test centers are accredited and independent, we also offer our services to R&D projects. Your tests and test results remain in full confidentiality.

Full engineering advice or test only

We can advise you on the best testing methodologies, carry out the tests in a controlled and accredited environment, help you understand the test results, and even provide you engineering advice, so all your components are fit for your on-site conditions.

As an accredited test center, we also offer our services to R&D projects, where we only carry out the tests as per your needs. Your tests and test results remain in full confidentiality.

Lightning tests

|

Initial Leader Attachment Test |

Determines likely lightning attachment points on the test sample. Test follows IEC 61400-24. |

|

Subsequent Stroke Attachment Test |

Predicts possible puncture locations in or close to the swept area. Test follows IEC 61400-24. |

|

High Current Arc Entry Test |

Assesses the level of damage at the possible lightning strike attachment points. Test follows IEC 61400-24. |

|

High Current Conducted Current |

Assesses the impact of electro dynamical forces and heating. Test follows IEC 61400-24. |

|

Electrical Resistivity and Conductivity |

Determines the resistivity or conductivity of solid materials. |

|

Electric Strength of Insulating Materials |

Determines the electric strength of solid insulating materials under voltage stress. Test follows IEC 60243. |

|

Electric and Magnetic Field Immunity Test |

Verifies the performance of electronic equipment and installations close to the lightning strike. |

|

Power Frequency High Current Test |

Verifies the performance of equipotential bondings and the current carrying capability of different conductor geometries. |

|

HVDC Tests |

Used for non-destructive verification tests and for simulating static discharge. |

Weathering tests

|

Rain Erosion |

DNV-RP-0171 |

Recommended practice to test liquid impingement erosion using rotating apparatus |

|

ASTM G73-10 |

Standard test method for liquid impingement erosion using rotating apparatus |

|

|

Xenon-arc Lamps |

ISO 16474 |

Paint and varnishes – Methods of exposure to laboratory light sources |

|

ISO 4892-2 |

Plastics – Methods of exposure to laboratory light sources. Part 2: Xenon-arc lamps |

|

|

ASTM G155 – 13 |

Standard practice for operating Xenon Arc light apparatus for exposure of non-metallic materials |

|

|

Fluorescent UV |

ISO 4892-3 |

Plastics – Methods of exposure to laboratory light sources – part 3 Fluorescent UV lamps |

|

ISO 16474-3 |

Paints and varnishes - Methods of exposure to laboratory light sources. Part 3: Fluorescent UV lamps |

|

|

Gloss |

ISO 2813 |

Paint and varnishes – Determination of gloss value at 20°, 60° and 85° |

|

Offshore |

ISO 12944-9 |

Paint and varnishes – Performance requirements for protective paint systems for offshore and related structures. |

|

Salt Spray |

ISO 9227 |

Corrosion tests in artificial atmospheres – Salt spray tests |

Tensile tests

|

Tensile - General |

ISO 527 part 1, 2 and 3 |

Plastics – Determination of tensile properties Part 1: General principles Part 2: Test conditions for moulding and extrusion plastics Part 3: Test conditions for films and sheets |

|

|

ISO 37 |

Rubber, vulcanized or thermoplastic — Determination of tensile stress-strain properties |

|

Peel |

ASTM D 3330 |

Standard test method for peel adhesion of pressure-sensitive tape |

|

ISO 4578 |

Adhesives – Determination of peel resistance of high-strength adhesive bonds – Floating-roller method |

|

|

Shear |

ISO 4587 |

Adhesives — Determination of tensile lap-shear strength of rigid-to-rigid bonded assemblies |

|

Tear |

ASTM D-624 |

Standard test method for tear strength of conventional vulcanized rubber and thermoplastic elastomer |

|

ISO 34 |

Rubber, vulcanized or thermoplastic – determination of tear strength |

Compression tests

|

ISO 844 |

Rigid cellular plastics — Determination of compression properties |

|

ISO 604 |

Determination of compressive properties |

|

ISO 7743 |

Rubber, vulcanized or thermoplastic — Determination of compression stress-strain properties |

|

ISO 815 |

Rubber, vulcanized or thermoplastic — Determination of compression set |

Other tests

|

DSC (-90°C to 300°C) |

ISO 11357 part 1, 2 and 3 |

Plastics - Differential scanning calorimetry (DSC) Part 1: General principles Part 2: Determination of glass transition temperature and glass transition step height Part 3: Determination of temperature and enthalpy of melting and crystallization |

|

Density |

ISO 1183 |

Plastics - Methods for determining the density of non-cellular plastics Part 1: Immersion method, liquid pyknometer method and titration method |

|

Water Absorption |

ISO 62 |

Plastics - Determination of water absorption |

|

Shore Hardness |

ISO 868 |

Plastics and ebonite - Determination of indentation hardness by means of a durometer (Shore hardness) |

|

Climate Cycling |

Customer specific |

|

|

Customized Tests |

Customer specific |

|