Polytech

Digital supply chain transparency with IoT

Watch the video and get a sense of how this can be achieved.

Get your wind turbines in time and without any damage

Transporting and storing wind turbines require maximum safety. Any damage or delay will cost you lost production and hassle dealing with claims and repair.

Ensure your wind turbine manufacturer (OEM) has the right transport interfaces and monitoring system to protect your assets and to get your components in the most cost- and time-efficient way.

Our PUR interfaces and storage frames give you complete protection and preservation of your turbine components during transport and storage. And our Polytech Insight™ – Logistics Monitoring System gives you all the insights you need to manage your transport equipment assets, wherever they are.

The Polytech solutions

- WTG component interfaces (friction pads) in polyurethane (PUR)

- Universal storage frames with replaceable interfaces

- Global repair and refurbishment services of transport equipment

- Polytech Insight™ - Logistics Monitoring System (tracking of utilization and humidity)

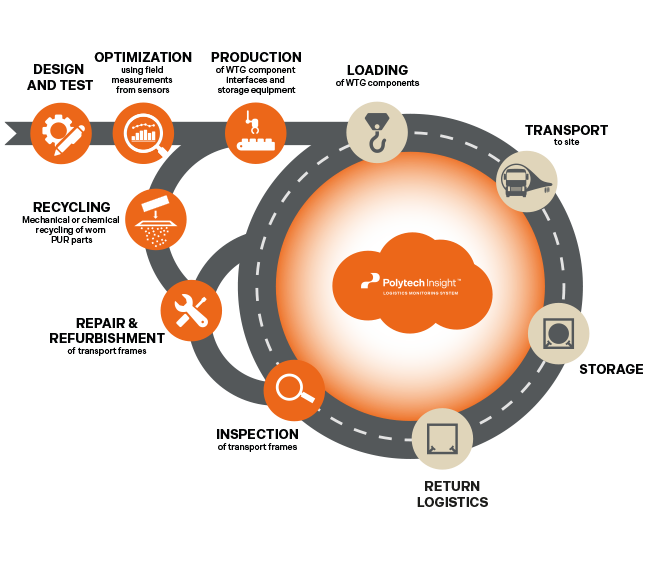

While these are individual solutions, they perfectly fit into a circular journey covering your entire project logistics, and therefore bringing additional value to the entire supply chain.

Circularity, traceability, and transparency during project logistics

Project logistics on a global scale can be overwhelming. A lot of segmented processes can make the logistics difficult to coordinate. And you might miss the complete overview, which can put pressure on your budget.

That is why we have developed all our transport solutions with circularity, traceability, and transparency in mind.

You can fully trace your project logistics with our Polytech Insight™ Logistics Monitoring System. Monitor your transport equipment’s location and availability. Monitor the humidity in your transported components. And monitor whether your turbine equipment have been inspected and serviced.

All our transport interfaces that are installed on the transport equipment can be recycled at our facility and integrated into new products with the same material quality. As such, they will carry on their circular journey and reduce your overall CO2 footprint.

If you are an OEM, you get...

- Top-quality and uniquely formulated PUR interfaces with designs that match the geometry of the individual structure perfectly

- Global repair and refurbishment services to ensure operational equipment

- Reliable transport equipment designs using our load verification field tests

- Up to 20% better utilization of your transport equipment, resulting in 20% reduction in your capital expenditures

- Full data log of humidity measurements

If you are an asset owner and your chosen OEM uses our solutions, you get…

- fully transparent asset management during transport and storage

- data log and documentation to support contractual agreements and insurance claims

Transport and storage interfaces

All our transport interfaces are tested extensively at our accredited testing laboratory.

We therefore ensure optimal friction, compression, shear loads, and bonding. The interfaces are also UV-resistant, have a high thermal resistance, and can be made with built-in fire retardancy to give your components extra protection.

The built-in RFID (radio-frequency identification) chips allow unique ID numbers for each pad with 100% traceability.

You get a top-quality interface due to a unique blend of materials. Our own PUR formulations ensure that every single interface is made with durability, reliability, and safety in focus.

Our own PUR formulation includes plant-based raw materials, which has lowered the CO2 footprint of every interface by 21%. Read more about this here.

Having full control over our material production, we can provide 100% recyclability of the interfaces at Polytech’s locations.

Polytech Insight™ - Logistics Monitoring System

See if your equipment is in use and how they are doing.

- Monitor where your turbine components are

- Monitor the status of the transport equipment. Is it available and ready for the next load? Is it in use, carrying e.g., a blade? Or is being inspected and refurbished?

- Record any incidents, e.g., shocks, during transport. It allows you to act quickly

Track humidity during transport and storage.

Track humidity inside the tower, nacelle, and power modules to see how often and howe long they are exposed to extreme temperatures or humidity. These events significantly impact the lifetime and quality of your wind turbine components.

Polytech Insight™ provides the overview of all assets and equipment usage – during transport, storage, inspection, and refurbishment.

OEMs will no longer need to waste resources on (re)ordering unnecessary transport equipment. With better utilization of transport equipment, they can optimize their logistics operations and planning. No more wasted kilometers on the road.

As Polytech Insight™ can improve turn time, it is easy to get on with any projects without wasting time or money. And with this, we all contribute to helping the planet: less produced steel, less waste, and less emissions.

Contact us

Get in touch with our Sales team directly or contact our Head of Transport Equipment & Solutions Torben Grue to learn more about how our solutions can optimize your operations.